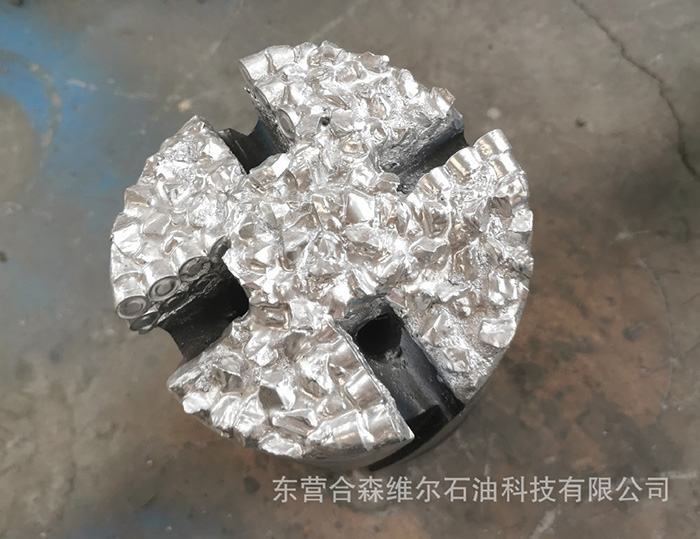

Efficient grinding shoes mainly include flat bottomed grinding shoes, concave bottomed grinding shoes, conical grinding shoes, collar eye grinding shoes, pear shaped grinding shoes, sleeve milling grinding shoes, and specialized tooth wheel grinding shoes. Flat bottomed grinding shoes are commonly used tools for grinding small objects underground and repairing fish tops. Concave bottom grinding shoes are used to grind small underground objects and other unstable objects. Leading eye grinding shoes are used for grinding and milling objects with inner holes that are shaking underground. Cone shaped grinding shoes are used to repair small local deformations of the casing and clean up debris on the wellbore.

Basic parameters of flat, concave, pear shaped, and tapered grinding shoes

Nominal outside diameter (mm) | Nominal outside diameter (mm) | Applicable wellbore size (mm) |

| 89 | NC26,2 3/8REG | 95.2~101.6 |

| 98 | 107.9~114.3 | |

| 110 | NC31,2 7/8REG,3 1/2REG, | 117.5~127.0 |

| 121 | 130.0~139.7 | |

| 130 | 142.9~152.4 | |

| 140 | NC38,3 1/2REG,4 1/2REG, | 155.6~165.1 |

| 156 | 168.0~187.3 | |

| 178 | 190.5~209.5 | |

| 200 | NC50,4 1/2REG, | 212.7~241.3 |

| 232 | 244.5~269.9. | |

| 257 | 6 5/8REG, | 273.0~295.3 |

| 279 | 298.5~317.5 | |

| 295 | 320.6~346.1 | |

| 330 | 349.3~406.4 | |

| 381 | 406.4~444.5 | |

| 406 | 7 5/8REG, | 431.8~508.0 |

| 432 | 457.2~533.4 | |

| 534 | 558.8~660.0 | |

| 686 | 558.8~660.0 |