Victory TDX series segment milling tools

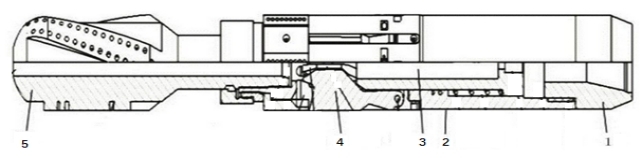

1. Tool structure (see Figure 1)

2. Technical specifications for TDX series segment milling tools (see Table 1)

3. Working principle: After starting the pump, the tool piston descends under the pressure difference, and the lower push plate of the piston pushes the blade to open; After stopping the pump, the piston resets under the action of the spring, and the blade automatically retracts.

Figure 1-1- Upper joint; 2- Body; 3-piston; 4-blade; 5-Centralizer

Forging and milling parameters (see Table 3)

Table 1 Technical specifications for TDX series forging and milling tools

Tool model | Connecting threads | Maximum body outer diameter (mm) | Outer diameter when the blade is retracted (mm) | Maximum outer diameter when the blade is opened (mm) | Total length of tools (mm) | Maximum outer diameter of stabilizer (mm) | Outer diameter of forged and milled casing (mm) | Wall thickness of forged and milled casing (mm) |

TDX-245 |

NC50 |

210 |

214 |

273 |

1780 | 222 |

244.5 | 8.94 |

220 | 10.03 | |||||||

218 | 11.05 | |||||||

216 | 11.99 | |||||||

TDX-178 |

NC38 |

144 |

144 |

210 |

1470 | 158 |

177.8 | 8.05 |

156 | 9.19 | |||||||

154 | 10.36 | |||||||

151 | 11.51 | |||||||

149 | 12.65 | |||||||

147 | 13.72 | |||||||

TDX-140 |

NC31 |

114 |

114 |

170 |

1290 | 121 |

139.7 | 7.72 |

118 | 9.17 | |||||||

115 | 10.54 |